An new standard has been launched. How do you build in a new standard within your daily operations of your CSSD. Every CSSD needs to work with a certain quality system. Today hydrogen peroxide becomes an official part of the group sterilization media with the installation of the ISO 22441. Within the CSSD you need to have a system to follow new developments according to regulations and standards. How can you make sure you don’t miss anything and how do I know what’s important. Is reading the standard myself essential and a must or can I find this information elsewhere?

We will talk about validation, final release (parametric or CI/BI supported), instrument compatibility and considerations when buying a new hydrogen peroxide sterilizer.

ISO 22441 is replacing ISO 14937 as the reference standard for H2O2 LTS across the world. Like all new standards guidance are useful to explain the intent of the ISO committees and ensure correct interpretation of normative language. Each normative paragraph of the standard will be commented, in particular the role of all parties involved in the development and implementation of a sterilization process (Sterilizer manufacturer, Medical Device manufacturer and end users) will be explained and a parallel will be made with other sterilization modalities

Hydrogen peroxide was captured within the ISO EN 14937. It was always difficult to determine the “critical” parameters to release your loads. In most of the cases you looked at the print-out and normally it says, “cycle completed” or “cycle successful”. In this new standard you will see that the word critical does not exist. Only the variables are named: pressure, temperature, time and H2O2 concentration. Where it seems logical that H2O2 concentration feels like the most important the manufacturer decides which combination of variables gives you certainty about your sterilization process. Is the new standard telling us something about using CI’s or BI’s to release loads.

Validation is and stays one of the basics in assuring the stability of your sterilization process. ISO 22441 does not change a lot in the way how to perform the validation. It is similar as the ISO 14937. This means IQ, OQ and PQ. And needs to be repeated yearly and after major repairs, this for every operating cycle. Important to take in account is that you need to find out your worst-case scenario for every performed operational cycle. This by using you most challenging device or a specific designed PCD.

The new MDR 745-2017 applicable from May 2021 pushed a shock thru the medical device landscape. Manufactures are still working hard to make sure everything gets certified on time. On the other hand, certain product lines are abandoned. When talking about sterilization, manufacturers know need to perform very strict cleaning, disinfection and/or sterilization validations. With the new ISO 22441 validating an instrument for hydrogen peroxide becomes more clear. You can validate a process not a combination with a specific hydrogen peroxide sterilizer.

As a footnote, what if I want to buy a new hydrogen peroxide sterilizer. For now there not yet an published standard for H2O2 sterilizers (EN 17180). From the moment the ISO 22441 is acknowledged within your normative institute you can use it for a tender. The manufacturer needs to comply to the process as described. On the other hand you can keep using ISO 14937 also. It’s best to describe both of them in your tender.

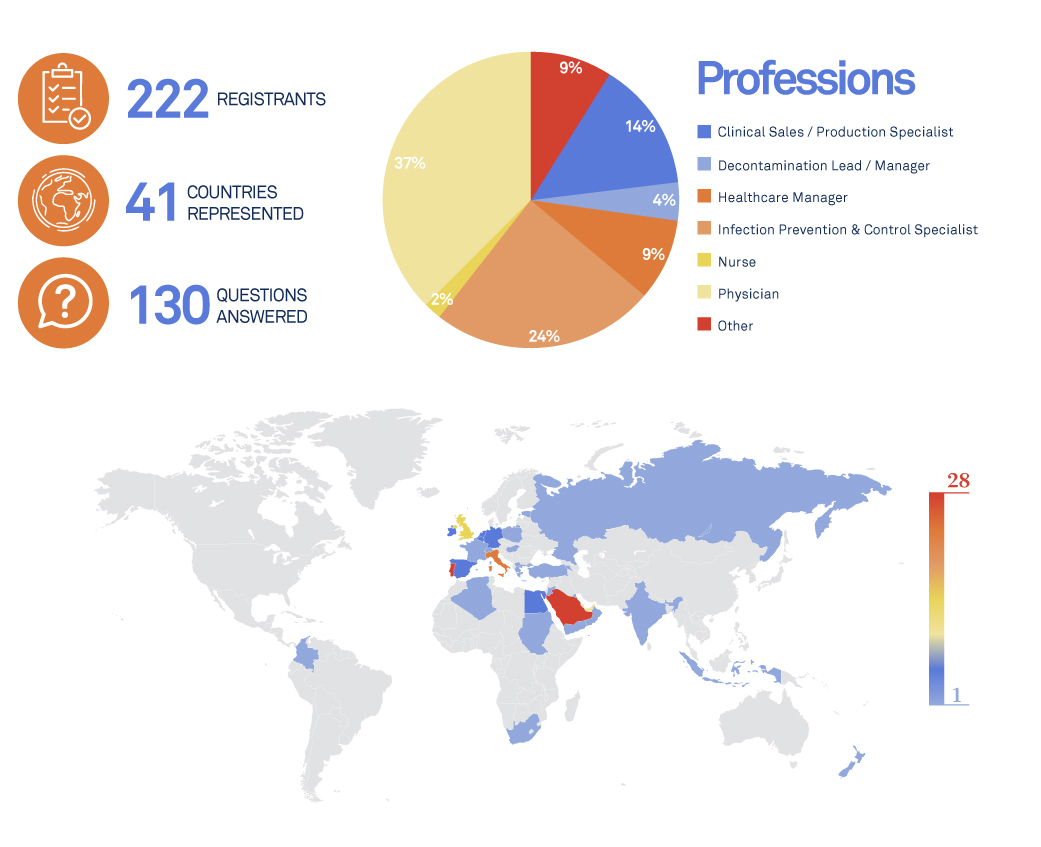

This is the second webinar dedicated to “ISO 22441 – The new standard for H2O2 sterilization”, presented by ASP Continuous Education.

27th JUNE 2024

Dr. Philippe Destrez

- Over 35 years experience in medical device industry including 25 in sterilization and disinfection in R&D and Management functions

- Currently Scientific Director ASP

- Member of various ISO and EN committees including and in particular those in charge of H2O2 standards: ISO 22441, EN 17180, ISO 11138-6

- Contributed to French and WFHSS sterilization guidelines

- Degrees in Physics and Management – based in Paris France.

Mr. Wouter Meert

- 25 year experience within operating room and hospital decontamination in University hospital Leuven. Current process and project manager CSSD and OR, instrument management lead.

- Member of the superior health counsil, ministry of Healthcare. Infection prevention, development Belgian guidelines.

- Memer working groups ministry of Healthcare.

- Board member VSZ (Flemish sterilization Society)

- Teaching sterilization courses in various schools (BANABA OR and CSSD management, basic courses sterilization.

- Training in risk analyses, ISO 13485, MDR 2017-745, auditor.

- Speaker at various congresses

MESSAGES

- Compliance to ISO 22441 process standard =

- Sterilizer, BI and CI, packaging manufacturers for compliance to applicable paragraphs of ISO 22441 and/or other standards

- Medical device manufacturer in partnership with sterilizer manufacturer for sterility and compatibility evaluation of medical devices

- Healthcare facility For the definition of load according to IFUs, supervision of validation, routine control, load release and maintenance of process effectiveness

- Applicable guidelines and regulation For example for use of BI , BI PCD or CI

- Find for yourself the way to understand the content and impact of the new ISO 22441 norm on your CSSD;

- Use the new variables pressure, time, temperature and H2O2 concentration together if necessary with BI our CI to define your load releases

- Defining a well thought out worst case for your hydrogen peroxide cycle validations builds in more safety in the process.

- ISO 22441 will help you to safely connect new medical devices with your hydrogen peroxide sterilization process.